[[{“value”:”

Thank you for reading this post, don't forget to follow and signup for notifications!

In case you haven’t heard, there’s been quite a commotion in the 3D printed-2nd Amendment (3D2A) world, a hand cranked, belt-fed, 3D printed minigun. Dubbed the M1337, this project is the brainchild of a 3D2A enthusiast known only as “Nopel”.

The following is an email interview I conducted with Nopel. It is extremely text heavy, so I’ll try to break it up with pictures.

I have made a couple small edits for typos and spelling, not for content. The term 3D printed/2nd Amendment (3D2A) is used extensively to describe printed gun parts and accessories.

An evening (email) with Nopel:

- Tell me about your first project, the RBC9. How did you decide to get into 3D2A, and how did you land on the RBC as your first design?

I originally got into 3D2A as a topic, as a sort of natural progression of the two main hobbies/interests of mine, that being firearms and 3D animation or modelling as a whole. I had always wanted a 3D printer, but only really felt they had become affordable and user-friendly enough around 2019 or so. I saw having one as a way to achieve a few projects I had in mind, some of which were firearms related, to make otherwise effectively unobtainable accessories for some of the firearms I owned.

After a while of using the CR10S that I had, I thought it would be fun to try building a gun using it. The fosscad megapack had been sitting on my computer for quite a while so I looked through it and decided to try out the FGC-9 MK1, which after sourcing a hardware kit went rather well, with some hiccups figuring out print settings better suited for this sort of project.

During this time, a video was uploaded to youtube showcasing the “Megapistol” designed by Humphrey Wittingsworth IV, which is/was a fascinating mechanism with an internal magazine ring that was indexed by the cycling of the slide. Most all the gun was printed, spare for the Bolt Face and pins/springs/etc. But importantly, this was I would argue an objectively beautiful looking gun, very art-deco looking in my opinion, and this was really the point where it clicked in my head that 3D printing can be a useful means of artful expression within the firearms space.

It was at this point that I essentially had the thought of “It surely can’t be too hard to design my own gun- why not try to do an FGC-9 but also belt fed?” There was a point in HW4’s video where from what I remember, he said something to the effect of “Just be persistent and it will work out eventually” in regards to designing something of your own, and that resonated with me a lot. It made me want to try to use what I knew in 3D modelling to create a gun design that didn’t already exist, that just sounded very cool to me, and I felt like I could do it if I just refused to stop working on it when it would inevitable hit a bump in the road, of which it did many times.

So with the main goal in my mind being to make something purposefully unique, I deliberately tried to avoid looking into how any other existing belt-fed systems worked. The RBC-9 overall was developed in a backwards manner of modelling out the overall shape as I would for use in games/animation, which was all I was used to, and from there figuring out all the internal workings. The “R” in RBC being “roller-delay” only came into the design about a year and half after starting, as a last-ditch attempt to make the action cycle, due the bolt being severely underweight, as a result of this frankly flawed outward-in sort of design process. There wasn’t any room to make the bolt heavier, so of course why not try to just cludge a roller-delay system into it? But it did actually work rather well at first, so it stuck. Presently the RBC-9 as a design is not where I would like it to be in terms of reliability, but hopefully some future changes can remedy that.

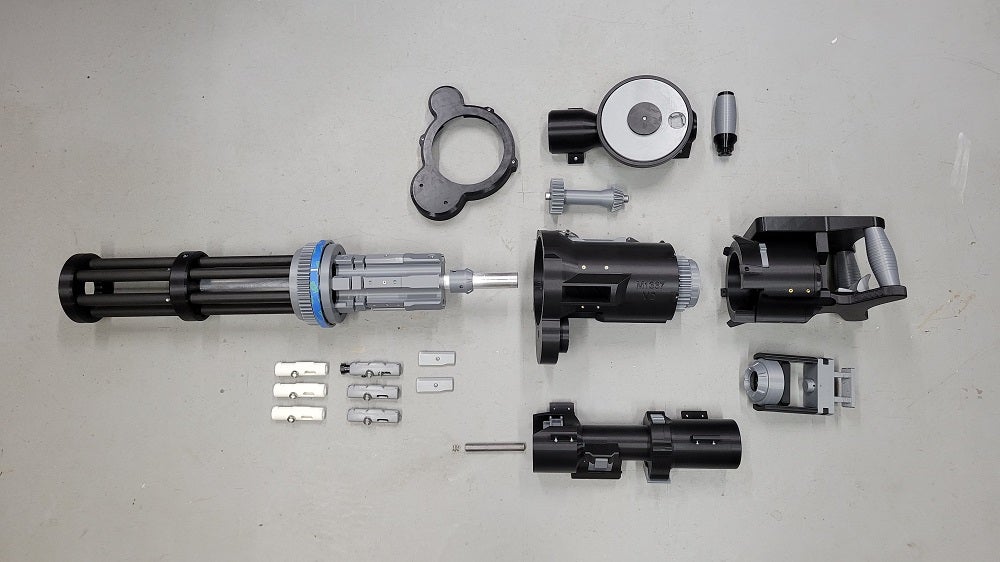

- Can you give us a breakdown on the M1337, what it is and what makes it unique?

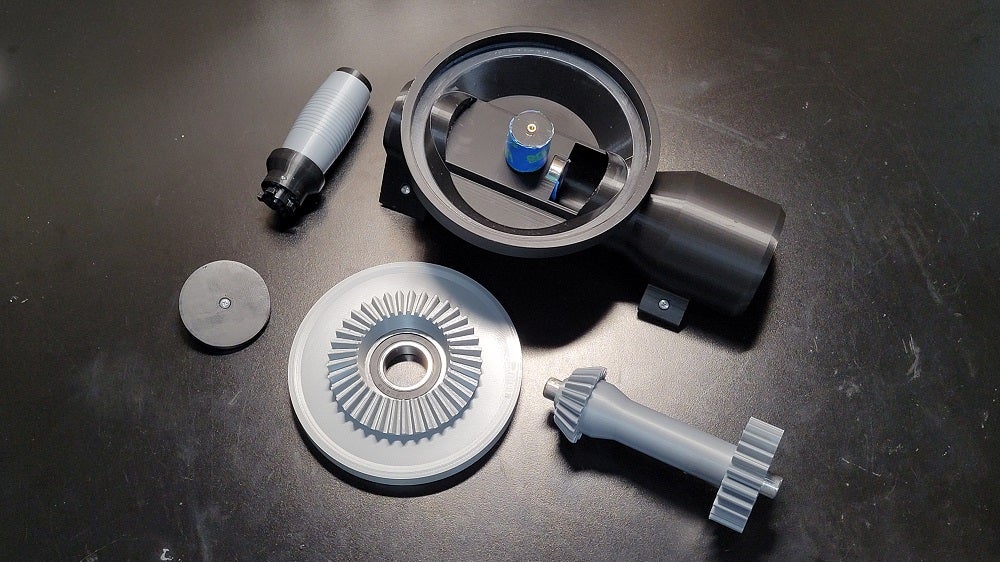

The M1337 is fundamentally a DIY gatling gun, but what I believe makes it most unique are a few things. Number 1: the internals are structured around exploiting the AR-15’s locking mechanism in the Bolt Heads and Barrel Extensions, which intrinsically has a small footprint and is very self-contained, in addition to being very accessible in the US firearms parts market.

Secondly, is the fact that a project like this simply couldn’t have been (reasonably) possible 10 or fewer years ago, and would have even been rather a lot harder than is was to develop even just a few short years ago, before the progression of the consumer 3D printer market from what I’d call sort of gen-1 consumer printers (Ender 3v2, CR10, parts-bin looking I-3 designs), to “gen-2” consumer printers (Bambu X1 clones and similar cascading improved designs).

I would surely have not enjoyed developing this whole project on my CR10, the speed difference on modern printers really allows for a project of this physical size to be feasible to the average person to build in a reasonable time frame.

These two main points together, make the M1337 the first gatling/rotary barrel gun or “minigun facsimile” design that is actually attainable in a way that is not exorbitantly expensive, or gate kept to people with special licensing. And that may not sound like much to some people, especially non-gun enthusiasts, but I think many would agree the gatling gun is representative of a sortof “pinnacle” or at least very high up on the list of guns that would be awesome to own, thanks to movies/games/mechanical intricacy/etc.

But perhaps most importantly, is that 3D printing allows such a design to be done in a way that *looks good*, not like a garage built cludge of parts, but rather a proper put-together thing, that is I’d argue better than the sum of its parts. I didn’t design the M1337 in the same form-over-function way as the RBC-9, but I did make every effort to keep the aesthetics of it in mind throughout, as I believe that is very important to firearms design.

- How many design iterations did the M1337 go through, and what were some of the specific issues solved by the various versions?

Throughout the development of the M1337, the design went through around 4 main iterations, those being Alpha V0-5, which were never released to the public, then Public Beta Version 1, Beta Version 2, Beta Version 3, and now finally the full Release Version 1.0.

The 3D2A space is truly a unique space, especially within the broader firearms space, as a massively collaborative effort involving so many smart and diligent people. The “beta” process has varying forms around the different groups within the 3D2A space, but the desired outcome of taking what are necessarily home-brew designs, and refining them to be consistent and/or enjoyable to build, is the ultimate goal for everyone involved.

Having the public beta versions of the M1337 was indescribably helpful to troubleshooting the issues that were present at the release of B1. So much feedback from a long list of builders went into working out where there were mechanical issues that either my own test gun didn’t ever experience, or I simply couldn’t see as a result of how hard it is to tell what is going on inside the M1337 when it is cycling.

B1 primarily had a lot of failures to eject, which was ironically being caused by the secondary ejector, and so that part was removed from future iterations. Beyond that it was mostly varying scenarios in which rounds would jam or get wedged at funny angles as they were fed along the path from the delinker into the barrels. A series of additional feed ramps and other changes were made across B2 and B3 to remedy these. B3 also made disassembly much easier to clear jams, as it was very tricky and annoying to disassemble B1 and B2 when stoppages would occur. The release version is very similar to B3, with minor dimensional changes to some of the parts for better overall fitment.

- Now that the design has left beta and hit full release, what else do you have planned for this design before you eventually move on?

Now that the release version is out. I think the belt box could be improved a bit. It doesn’t feed when fully loaded, which isn’t ideal, but it works well enough for the moment as described in the user manual. As well a second belt box for use off the ground that holds more ammo would be a good addition.

I would really like to try a secondary crank housing design that could possibly use a planetary gear setup to further gear-down the rate of fire. As gatling guns are effectively considered to be several bolt-action rifles as far as the NFA is concerned, rate of fire is generally not something that determines the legal status of gatling guns. What sets the minigun and similar things apart is the presence of an electric motor. So a crank with a faster output speed would still be manually operated.

- .300 AAC Blackout was mentioned as having been tried in the m1337. How has that gone, and how does that look to be going?

I do have a set of 300 Blackout barrels in a separate barrel cluster. I’ve so far tested it only a couple times. A fellow developer by the username Nikolai Romanov designed a massive printable suppressor specifically for the M1337 called the Pr17 Malachit, and so I properly Form 1’d one of these and printed it out to test with the .300 blk barrel set. On paper it should work with no issues, .300 blk being a 5.56 parent case and all, but it does seem to have issues with weak ejection that leads to a lot of FTE stoppages. This may just be an issue of my own bolts that I’m using but I’m not sure. I think better ejector springs or those dual-ejector bolt heads would help remedy the issue. But it is another unique thing to have .300 blk be an option; there are suppressor for miniguns and such, but there aren’t any miniguns or existing gatling guns chambered in an already subsonic cartridge like 300 blk. It is really very quiet when using the Malachit with the M1337 in 300 blk.

- A previous interview you did mentioned a ~400 round count had been tested, and no true “burn down” testing had been done. What’s the latest info on those aspects?

Total on my own test gun I have probably around 500 or so rounds through the current iteration, which isn’t much really, but I have been swapping parts around a lot so its hard to say how many rounds have gone through all iterations combined. As far as burn-down testing, the most I’ve put through in one string of fire has been 80 rounds, as I ran out of ammo that particular day after those 80 rounds, but I’m positive it would have gone for much longer. Based on extrapolating the burn-down results from the Orca that people have tested, I suspect 180-360 or so rounds, depending on the type of polymer used to print it out, would be a reasonable assumption of continuous fire through the M1337 before heat would deform the barrel cluster to the point of possibly causing issue. I’ve never personally had a stoppage or other issue as a result of heat buildup while firing. Because of the way the barrels are mounted, even when heating up they won’t tend to sag as they are held out front by the Barrel Collar / are not free floated

- Whats the estimated length of time for a new user of 3d printers to print and finish an m1337? An experienced user?

Total print time for the M1337 is about a week or so of print time. But critically, I’m assuming this with the print speeds made possible by current-gen printers. As said before, if I had to print this whole design out on my old CR10s I’d probably think twice about doing so, as it’d take at least triple that time. This is also the case with printing one out in all Nylon or similar engineering filament, as most have to be printed much slower than modern PLA+.

For the entire build overall, I think a person new to 3D printing could assemble an M1337 in probably a month or two, assuming they already have some firearms knowledge coming into it. Really where they’d get bogged down would likely be troubleshooting any issues with cycling. I don’t feel the build itself is too hard, as its mostly large parts that fit together pretty easily, but working on the tolerances of the Bolts can be tricky if making all the pieces by hand.

For an experienced builder, I’d say probably a week or two of time. Each major component takes enough time to print that the previous print can be processed and assembled in the time it takes to print the next one, if all the necessary hardware is already on-hand.

- Minimum printer you would recommend for printing a m1337?

Personally I’d recommend a Bambulabs printer, as its what I have and very much like, but I know many people have reservations regarding their ability to potentially lock-down functionality of the machines in the future due to the closed-source nature of their products, as well as the possible privacy risks that could arise. There are many similarly good printers that are more open source, as much of the 3D printing market played catch-up with the Bambu X1, to where much of the landscape now is clones or competitive options. In general any printer with a build volume that is larger than 220×220 should be able to fit all the parts on the build plate, but it wouldn’t hurt to download a slicer and import the stl files to check for yourself if you are unsure if a particular machine will work.

- Regarding your own beliefs as they relate to politics and liberty, what does the 3D Printing/2nd Amendment (3D2A) movement mean to you?

I think most people, especially those not really into guns or even outright against guns overall, view the 3D2A/GunCAD space from a perspective of it being particularly dangerous or anarchist in a way. I think the first thing anyone asks that isn’t aware, is something along the lines of “Is that legal? Is that safe? etc”, generally people approach the topic with curious skepticism or a bit of worry.

There is no doubt an underpinning of defiance and freedom overall within the 3D2A space, as its the most direct way probably ever of showing that gun laws simply won’t be able to beat out people’s will to secure their means of self defense. The most obvious and quoted examples being in Myanmar with many cases of documented use of printed firearms in the rebel factions.

But I think as mentioned above, the 3D2A space has a flip side to that entire aesthetic, that is one of pure artful expression using firearms as a medium. The 3D2A space has such a concentrated gathering of smart individuals from wildly different political leanings and professional backgrounds coalescing around a shared topic of interest. To the vast majority of people, whether gun-experienced or gun-shy, that I’ve ever shown my own projects to, the response has been positive, because most people can recognize that there is an inherent art form to it all. I just wish I could beam the thoughts of my own outlook on the topic into people’s heads so to speak, to get past the initial “is that legal/safe” worries and explain that it isn’t intrinsically dangerous or some kind of “dark underbelly” but for the most part is just people having a good time building cool things for fun because they can.

Doing guncad related projects has been some of the most fulfilling stuff I think I’ve ever done, because it has allowed a creative outlet for so many different interests of mine; guns, 3D modelling, video production, audio production/songwriting, graphic design, etc. And I know many other people are in the same boat.

I think 3D printed guns represent an on the nose example of craftsmanship and artistic expression as it relates to guns, which is an avenue to make people maybe politically averse to guns better understand (the correct) viewpoint.

- Do you feel the 2A3D movement adds to the commercial gun market, or subtracts from it?

I feel the 3D2A space adds to the commercial gun market for sure, in some direct and indirect ways. Indirectly, the sheer amount of ingenuity and creativity on display either by necessity of limited resources in DIY builds, or as a purposeful endeavor for a design to be bespoke, I think is or should be a wake up call to the broader firearms market that a lot of people just want more cool out-of-the-box stuff. For a lot of people arriving at printing your own gun builds is likely a symptom of being so far down the iceberg of gun owning/building, so to speak, that its the current frontier of cool unusual stuff, and if more big companies invested resources to having more interesting offerings, there’d be a sizable market of people willing to partake.

In a more direct way, the 3D2A space has in many ways revitalized the parts-kit market. More and more parts kits are being purchased with specific intent to build using existing 3D-printed designs. A poignant example of which being the AUG and its printed NylAUG variant. Most AUG demill parts sets imported into the US lack receivers, and even if they had them it is very difficult to re-weld or do anything with it to make a functioning firearm from it. The Nylaug is a 3D printed project that utilizes those AUG parts kits, built around a Nylon printed polymer receiver. I’d wager that nearly all AUG kits sold in recent years have been built into NylAUGs, and likely a smaller majority of CETME-C, CETME-L, and other such kits have been built into one of the 3D-printed builds meant to utilize them, as opposed to the much more difficult and time consuming process of building them from 80% receivers or receiver flats and etc.

So I think the 3D2A space does directly influence a large amount of commerce throughout the firearms industry, and will only continue to do so with greater intensity as time goes on.

- What are the strengths and weaknesses of additive manufacturing vs reductive machining?

I have had issues (with the M1337) with heat from the sun / air temperature, and this gets to the main issue of printed designs overall, that being an inherent fragility to many of them. PLA+ is a wonderful material with an achilles heel of rather low heat resistance. Carbon-Fiber infused Nylon I think is generally considered to be the standard for printing guns in something more serious than PLA+. It has very high heat resistance and good impact resistance, but at the cost of higher price and slower print times, in addition to requiring a printer that can actually print the material, but with most gen-2 consumer printers this isn’t an issue.

In the case of the M1337, PLA+ is well suited due to the high speeds which it can be printed, as well as the much cheaper cost for the filament as compared to other materials, but it does mean that the gun has to be treated somewhat carefully, as weighing in at around 25 pounds on average, dropping it would no doubt cause several things to break. Furthermore in PLA+, leaving it exposed to overly hot air temperature for too long will cause things to warp and could lead to mechanical issues and the need to reprint parts.

But contrasting this, 3D printing allows for a much more free-form design to be possible, as the limitations of what is physically possible on a CNC mill or lathe is irrelevant. I suspect it would be very hard or nearly impossible to machine certain parts of the M1337, which I would note is also reflected in the gun industry as many actual miniguns are utilizing 3D metal-printing to form the complex geometries of those designs, including some or maybe most all of the suppressors made for them.

There are a few additively manufactured steel-printed parts that can be used in the M1337, and it is shocking how good parts made in this way can be. The downside presently is cost and time, as lead times for the almost exclusively foreign sources of affordable metal-printing can be rather long, and the cost doesn’t effectively scale down with larger quantities for the most part.

- Describe your dream design.

My dream design of sorts I think would be sortof one of two things. In the immediate future, I would like to try and make a proper 5.56 chambered belt-fed that could be a facsimile of a SAW. Most all belt fed firearms on the market are very expensive, and I think much like the market for gatling guns, it’d be good to have a DIY project to make a SAW type belt fed attainable to the average person, especially considering the current proliferation of the Super-Safeties/FRTs. Looking outside the 3D2A space, the Lima-6 Belt-fed AR15 upper is a great example of this, offering a very good reliable belt fed to the average person at a much more affordable price than any of its competitors.

Thinking far into the future though, I think its a safe assumption that eventually 3D Metal-printing machines will be something that could be purchased similarly to a small lathe or mill. I don’t think it’ll ever be to the point of getting a metal-printer from Microcenter, due to inherently not being a hobby level machine, likely needing strong power requirements, potentially hazardous metal powders, etc, I think it’ll always be relegated to a shop-tool, but no doubt there will be a “bambulabs of metal printers” someday that makes that type of thing something a person could run out of their garage or basement. So with that in mind, I think it’d be cool to design a firearm for that use case. It may not be reasonably buildable now, but someday the tech would catch up such that it could be built.

- What’s next for you?

I do have a few other projects that are in various stages of being worked on. The BALR and RBC-9 are still unfinished, and I have every intention to finish both, along with a .22LR conversion of the HW4 Megapistol, which would be called the “Gigapistol”. There’s a few other projects that I’ve either not yet talked about, but presently work on those has been very slow.

That’s a wrap…

I’d like to thank Nopel for taking the time out of designing such complex projects to answer my questions.

Stay free!

–Jens “Rex Nanorum” Hammer

@Rexnanorum

“}]]