This is a review of EAW’s 3D-printed Lightweight Riflescope Mount. According to EAW, they are the first to use this technology on a mount, and they claim that their aluminum block mount saves around 30-40% in weight against comparable mounts. I was introduced to the new mount at IWA in Germany earlier this year, and EAW were kind to send me a sample for this review.

Thank you for reading this post, don't forget to follow and signup for notifications!

3D Printing @ TFB:

- New Anschütz Bionic: 3D printed Biathlon Rifle

- The Rimfire Report: How 3D Printing Saved My High Standard Flite King

- SIG Sauer MODX-45 Modular 3D Printed Suppressor Available Now

- 3D Printed Glock Backplates from Verex Tactical

- The Salen 3D Printed Titanium Compensator

To keep things as German as possible, I decided to test the mount on my Heckler & Koch MR223 with a Schmidt & Bender 1-8×24 PM II ShortDot Dual CC.

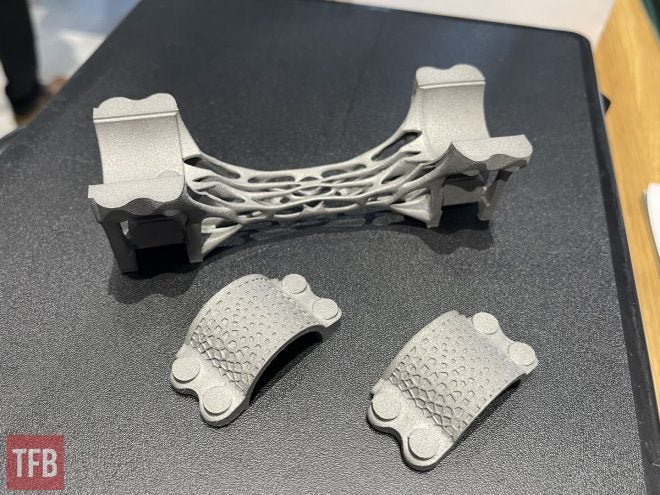

Below: Samples of metal 3D printed riflescope mounts from EAW, in different stages of the manufacturing process.

3D Metal Printing – Short Background

Metal 3D printers build parts by adding material one layer at a time based on the digital 3D design in a CAD file. With “Additive Manufacturing”, as the manufacturing method has been named, you can make items with geometries that are normally impossible to produce.

Below: EAW’s titanium mount – what it looks like from the machine.

Conventional subtractive manufacturing methods like CNC machining (where you take a block of metal and machine material away), would not work to make a mount like this. However, after the 3D printing process, the mount still needs post-processing in high-quality milling and turning machines.

3D printing is mainly popular in the aerospace and medical industries, but also the defense and automotive sectors look at the technology closely. As you can imagine, some of the drawbacks are price and lead time.

Below: Post-machining needs to be applied on some of the surfaces to finish the product (aluminum), to keep the tolerances to a minimum.

The balance of a rifle is extremely important to make accurate shots. Unfortunately, placing a heavy rifle scope in a heavy mount rocks the weight balance dramatically. Therefore, anything we can do to reduce the weight will be beneficial (unless you want a really heavy rifle for a specific reason).

Below: EAW’s picture of the left mount above, once the mount is ready. This new model is made of titanium. I love the “alien” design of the middle section.

Reduction of material (weight) from a part without compromising the mechanical properties is always a challenge. With 3D printing, you can maximize the mechanical properties, and still keep the weight to a minimum. According to EAW, their mount has been successfully subjected to endurance testing by DEVA with 2,500 shocks at 700 G of force.

Weight and Strength

According to EAW, the lightest 3D printed model weighs just 138 grams (4.867 ounces). This is the one with Ø30, 10mm height and screws. Any extras will of course add weight. The model with levers (as tested here) weighs 164 grams (5.784 ounces). The heaviest is Ø34, 15mm high model with levers, weighs 191g (6.737ounces).

Again, according to EAW, a mount milled from 7075 aluminum with the same stability would be 30-50% heavier.

Below: Threads cannot be 3D printed, so these have to be made traditionally.

About EAW

Since this is TFB’s first article about EAW here is a short introduction. The company was founded by Ernst Apel Sr. in 1919 and they are in fact the oldest working manufacturer of mounts in the World. After World War II, the business changed its name to EAW (Ernst Apel Würzburg) and began producing scope mounts. In 1970, they invented the pivot mount. They are located in Gerbrunn, a municipality in Bavaria in Germany.

Below you can see the mount reviewed in detail.

The EAW part number of the reviewed mount is 5744 “3-D Blockmontage schwartz für Picatinny 30 mm diameter BH10 mit taktischem Hebel.” That roughly translates to a 3D block mount in black for Picatinny in 30 mm diameter with quick detach. BH10 means that there is only 10mm from the top of the Picatinny to the bottom of the 30mm riflescope.

Below: The quick detach from underneath.

EAW’s 3D printed mount blends in well on the Heckler & Koch MR223. This rifle has a Troy carbon fiber handguard and a Geissele trigger, and shoots as could be expected. I absolutely love the Schmidt & Bender 1-8×24 PM II ShortDot Dual CC riflescope and only wish I could use it more and at longer distances, past the usual 300 meters.

In most cases, a mount for an AR should be between 32-38 mm in height. Unfortunately, and without knowing, I asked EAW for the wrong height, so I had to mount everything a little further back for it to fit on the H&K. This is hardly EAW’s or the mount’s fault, so I’m to blame. If you want a really low mount look no further, this version will do it! This version is about 12 mm lower than the lowest recommended AR mount. It would probably fit quite well on a Benelli MR1, some Tikkas or similar rifles.

Here you can see a series of images from EAW’s booth at IWA 2022, where they had larger riflescopes on display with their 3D printed mount. Can you identify the transparent rifle?

With an accessory to attach an Aimpoint Micro H-2 red dot.

Below: The Leica PRS 5-30x56i Riflescope which we reviewed two years ago.

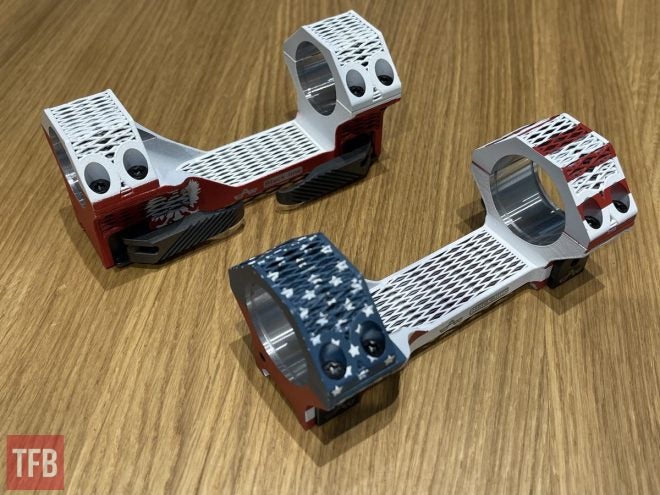

You can order the EAW’s 3D-printed mount in natural or black anodized aluminum. The one I got is obviously black, which seems like a good choice unless you really want to flash the fact that it is 3D printed? You can also order coating or have it added afterward. The mount is only made to advance order. The price is said to be in the region of 650 to 760 Euro (VAT included).

Below: Some patriotic examples of coatings.

Below: And the European Union coating of course.

Conclusion

3D-printed metal mounts are a novelty, and it’s interesting to be part of history in the making. Will 3D-printed mounts take over those made in CNC machines? No, for certain they will not, as CNC machining will be the prevailing production method for decades to come. Priced around 4 times more than a normal “economy” AR riflescope mount, it’s clear that this product is not for everyone. However, it does provide an interesting option for connoisseurs and customers who want something new and different.

Below: A 3D printed version of the Eiffel Tower I happened to have at home, with EAW’s3D printed mount. Custom TFB patch.

While I did not have any problems or issues with the mount in terms of quality or it keeping the zero, it did leave some marks on my riflescope, which is unusual.

If your new Rolex watch isn’t drawing you enough attention at the shooting range and you want a good-looking, made-to-order showstopper, then EAW’s Lightweight 3D-Printed Mount could be the solution. This 3D-printed mount would also be cool on any ultralight build.

You can find EAW’s homepage here: https://www.eaw.de/en